1. The Rise of Robotics in Manufacturing

In recent years, robotics has transformed traditional manufacturing by streamlining production processes, improving efficiency, and reducing costs. Robots are no longer just tools for heavy lifting; they are advanced systems capable of performing complex tasks such as welding, assembly, and quality control. As automation continues to advance, industries are adopting robotic solutions to meet the growing demands for precision, speed, and flexibility in production.

Key Features:

- Increased production efficiency

- Enhanced precision and accuracy

- 24/7 operational capacity

2. Automation in Assembly Lines: Efficiency at Scale

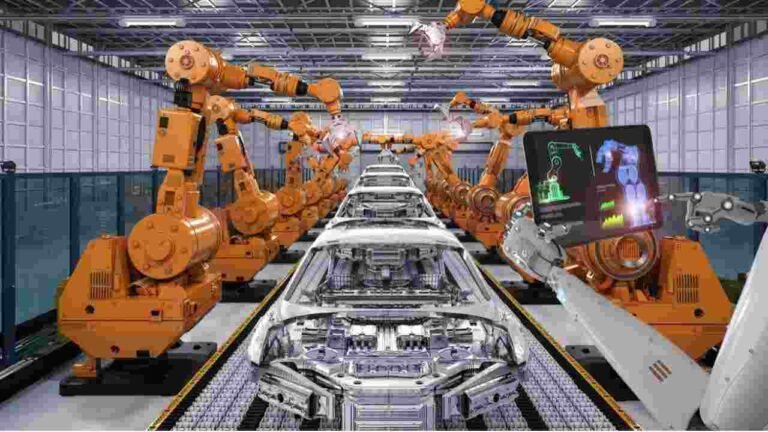

One of the most significant impacts of robotics on traditional manufacturing is the automation of assembly lines. Robots equipped with advanced sensors and AI capabilities can now handle intricate tasks that require high levels of precision, such as assembling electronic components, automotive parts, and consumer goods. Collaborative robots (cobots) work alongside human workers to assist with repetitive tasks, allowing for increased throughput and higher-quality output.

Key Features:

- Seamless integration into existing production lines

- Faster and more efficient assembly

- Reduction in human error and inconsistencies

3. Robotics in Quality Control: Ensuring Perfection

Quality control is a critical aspect of manufacturing, and robotics is enhancing this process by automating inspection and testing. Vision-guided robots equipped with cameras and sensors can inspect products at a faster rate and with higher accuracy than human inspectors. These robots can detect defects, measure product dimensions, and ensure that every item meets strict quality standards, all while reducing the risk of human error.

Key Features:

- Automated inspection and testing

- Enhanced defect detection

- Higher consistency in product quality

4. Robotics and Supply Chain Optimization

Robots are also playing a key role in optimizing supply chains by improving inventory management and logistics. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are now used in warehouses to transport materials and products to different areas of the facility. These robots reduce the need for manual labor, minimize delays, and ensure a more efficient flow of goods.

Key Features:

- Autonomous material handling in warehouses

- Real-time inventory tracking

- Reduced supply chain bottlenecks and delays

5. Robotics in Customization and Small-Batch Production

One of the biggest challenges in traditional manufacturing is the ability to adapt quickly to customer demands for customized products. Robotics is revolutionizing this by offering flexible solutions that can easily transition between high-volume production and small-batch customization. Robotic arms can quickly switch between different production tasks, allowing manufacturers to produce customized items, such as tailored automotive parts or unique consumer goods, without sacrificing efficiency.

Key Features:

- Flexibility in production for mass customization

- Quick changeover between production lines

- Capability for both high-volume and small-batch production

6. Cost Reduction and Labor Efficiency

While robotics initially involved significant upfront costs, the long-term savings are undeniable. Robots can work faster and longer than human workers, resulting in lower labor costs and increased production capacity. Additionally, robots can reduce waste, increase energy efficiency, and improve overall factory operations. As the technology advances, robotics is becoming more affordable for small and medium-sized enterprises (SMEs), enabling them to compete in a global market.

Key Features:

- Reduced operational and labor costs

- Increased productivity and throughput

- Long-term return on investment (ROI)

7. Collaborative Robots (Cobots): Enhancing Human-Robot Interaction

Collaborative robots (cobots) have emerged as a significant development in the robotics space, enabling robots to work directly with human operators in shared workspaces. These robots are designed with advanced sensors and safety features, allowing them to assist humans without the need for safety cages or barriers. Cobots are particularly valuable in industries that require human dexterity and decision-making alongside robotic efficiency.

Key Features:

- Safe collaboration between humans and robots

- Assisting with tasks that require human expertise

- Reducing repetitive strain on human workers

8. Robotics and Sustainability: Reducing Waste and Increasing Efficiency

As the manufacturing industry faces increasing pressure to reduce its environmental impact, robotics plays a crucial role in promoting sustainability. Robots are highly efficient in their use of resources, minimizing waste during production processes. Additionally, robots are capable of recycling materials, optimizing energy usage, and producing goods with minimal environmental footprints.

Key Features:

- Efficient use of resources and materials

- Waste reduction and recycling capabilities

- Energy-efficient manufacturing processes

9. Future Trends: AI and Machine Learning in Robotics

The future of robotics in manufacturing lies in the integration of AI and machine learning. As robots become smarter, they will not only automate tasks but also learn from their experiences to optimize performance. AI-powered robots will be able to predict maintenance needs, adjust production schedules based on demand fluctuations, and even improve the design of products based on real-time data.

Key Features:

- AI-driven automation and decision-making

- Predictive maintenance and optimization

- Real-time data-driven product improvements

10. The Impact of Robotics on Employment and Workforce Transformation

While robotics has greatly improved efficiency and productivity, it also raises questions about the future of the workforce. While some traditional manufacturing jobs may be replaced by robots, there is also an increasing demand for skilled workers to design, program, and maintain these advanced systems. The rise of robotics is prompting the need for reskilling and upskilling programs to prepare workers for new roles in automation and robotics.

Key Features:

- Shift in labor demand towards robotics-related roles

- Reskilling and upskilling opportunities in automation

- Transformation of manufacturing job roles and skills

Conclusion

Robotics is not just revolutionizing manufacturing—it’s transforming entire industries by improving efficiency, product quality, and customization capabilities. With the increasing adoption of AI, machine learning, and collaborative robots, the future of robotics in manufacturing looks promising. As this technology continues to evolve, it will reshape how we produce goods, optimize supply chains, and improve sustainability, ensuring that the manufacturing sector remains competitive and innovative in the years to come.